A food processor is a kitchen appliance that is designed to chop, shred, slice, and mix food quickly and easily. It typically consists of a base unit with a motor and a bowl, as well as a variety of interchangeable blades and attachments for different tasks.To use a food processor, you simply place the food you want to process into the bowl and attach the appropriate blade or attachment. You then turn on the motor and the blade or attachment will rotate, cutting, shredding, or mixing the food as it moves through the bowl. Some food processors also have additional features such as pulse buttons for precise control, and multiple speed settings for different tasks.Food processors can be used for a wide variety of tasks in the kitchen, such as:

Chopping and dicing vegetables and fruits

Production of food processor:

A food processor is a household appliance that is used to chop, slice, shred, and mix a wide variety of foods. It typically consists of a base unit with a motor, a bowl for holding the food, and various attachments such as blades and disks for performing different tasks.

The production of a food processor involves a number of steps, including:

1.Design and development: This involves creating the initial design for the food processor and refining it through testing and prototyping.

2.Raw materials sourcing: This involves acquiring the various raw materials that will be used in the production of the food processor, such as plastics, metals, and electronics.

3.Manufacturing: This involves using various tools and equipment to transform the raw materials into the finished product. This can include processes such as injection molding, metal stamping, and assembly line production.

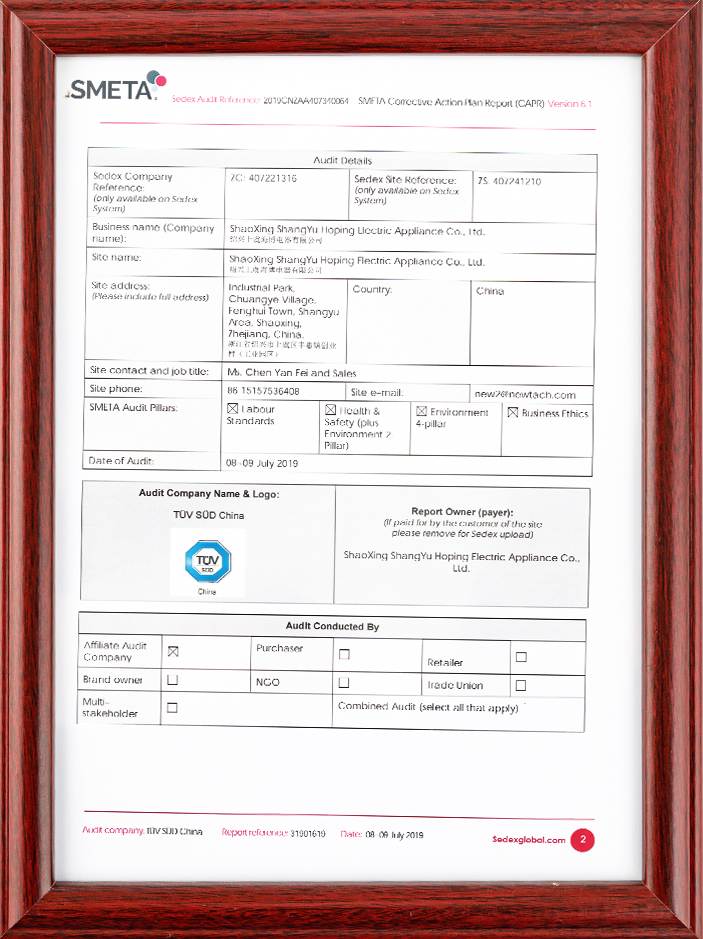

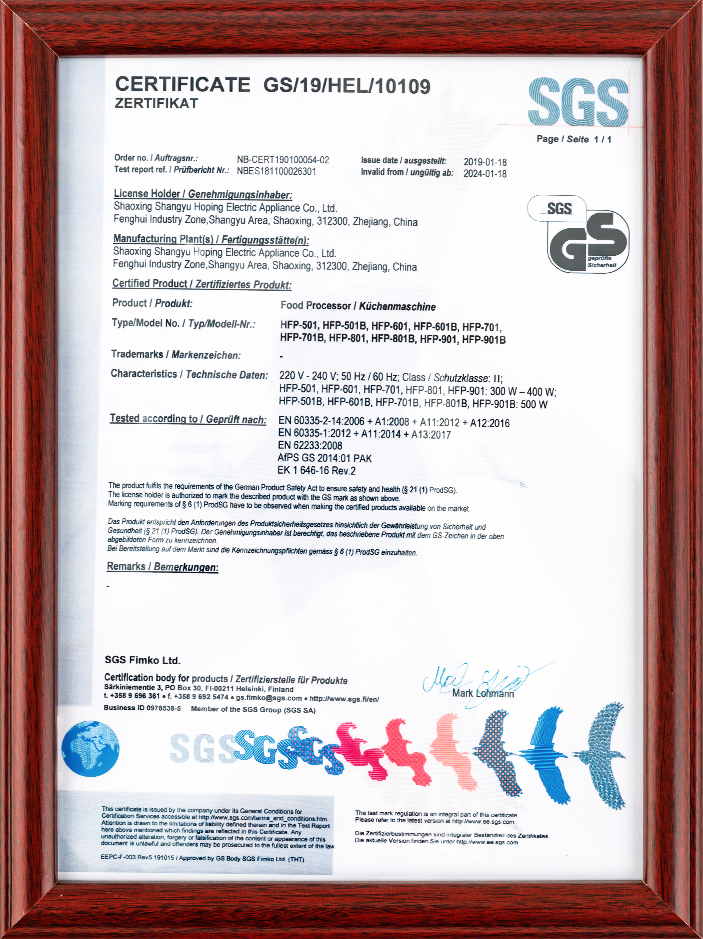

4.Testing and quality control: This involves ensuring that the food processor meets all relevant safety and performance standards before it is shipped to customers.

English

English 中文简体

中文简体

MORE

MORE MORE

MORE MORE

MORE MORE

MORE MORE

MORE MORE

MORE MORE

MORE MORE

MORE MORE

MORE