Introduce of shoes dryer:A

shoes dryer is a device that is used to dry wet shoes or boots. Shoes dryers come in a variety of styles and can be powered by electricity, gas, or propane. They typically have a heating element that generates heat to dry the shoes.

To use a shoes dryer, you typically follow these steps:

Step 1:Remove the insoles and laces from your shoes, if possible.

Step 2:Place the shoes in the shoes dryer and turn it on.

Step 3:Set the temperature and drying time according to the manufacturer's instructions.

Step 4:Allow the shoes dryer to run until the shoes are fully dry. This may take anywhere from 30 minutes to several hours, depending on the type of shoes and the humidity level.

Step 5:Once the shoes are dry, turn off the shoes dryer and remove the shoes.

Shoes dryers are a convenient way to dry wet shoes or boots quickly, especially in cold or wet weather.

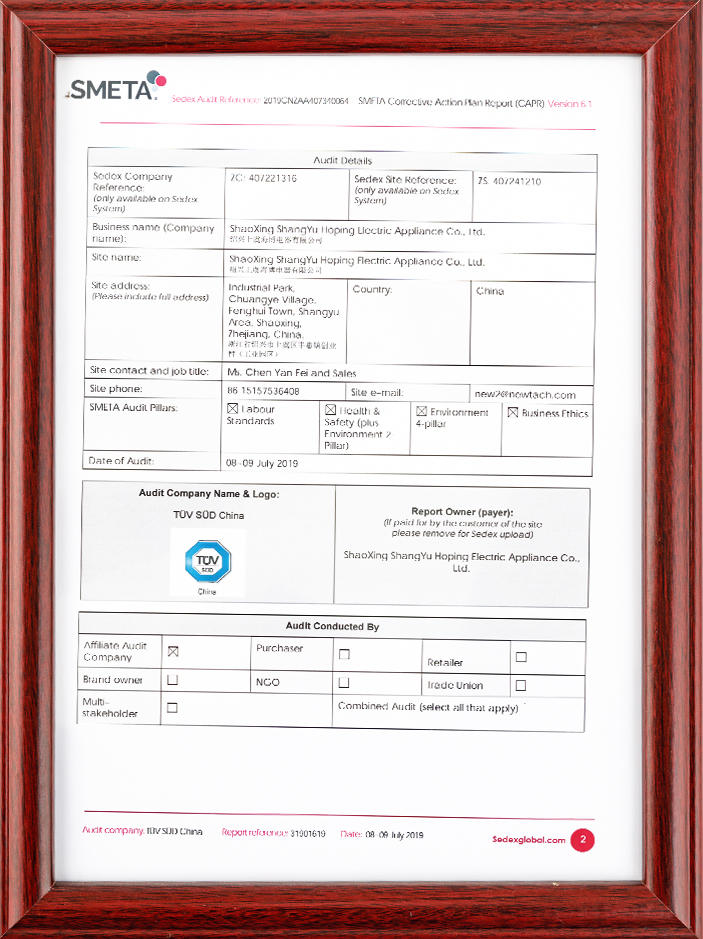

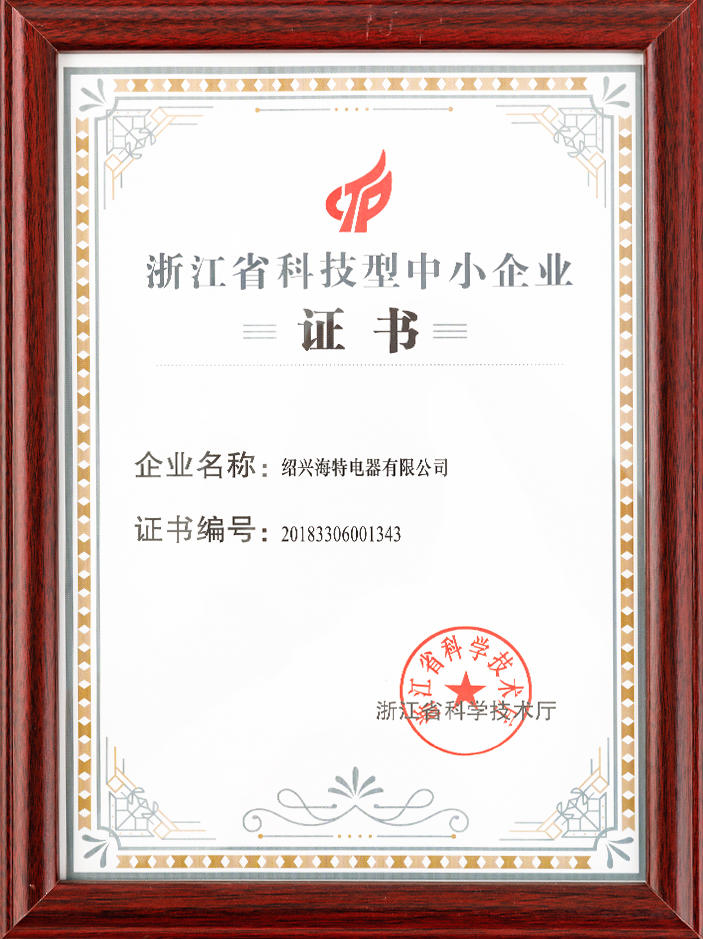

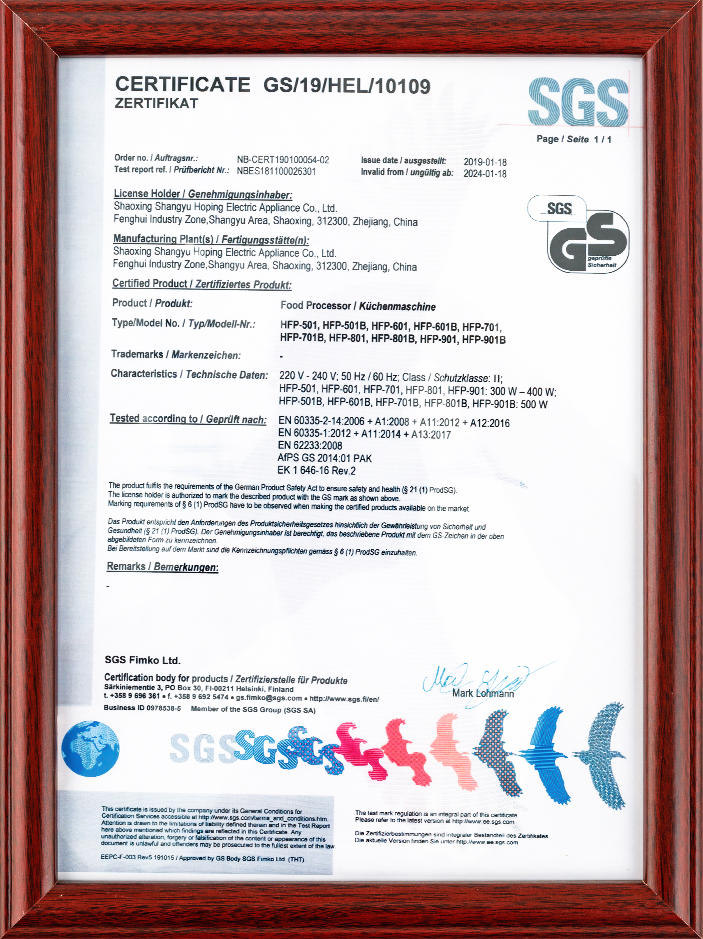

Shaoxing Shangyu Hoping Electric Appliance Co., Ltd is a company that produces and sells shoe dryers.

To manufacture shoe dryers, the manufacturer typically follows a series of steps, including:

Design and development: This involves creating the design and layout of the shoe dryer, including its size, shape, and materials.

Procurement of raw materials: The manufacturer acquires the raw materials needed to produce the shoe dryer, such as metal, plastic, and electrical components.

Fabrication: The various parts of the shoe dryer are fabricated using techniques such as injection molding, stamping, or casting.

Assembly: The various parts of the shoe dryer are assembled using techniques such as welding, gluing, or screwing.

Testing and quality control: The finished shoe dryer is tested to ensure that it meets the required specifications and standards. Any defective or faulty units are identified and repaired or rejected.

Production of shoes dryer:

A shoe dryer is a household appliance that is used to dry wet shoes, boots, and other footwear. It typically consists of a base unit with a heating element and one or more drying tubes or chambers for holding the shoes.

The production of a shoe dryer involves a number of steps, including:

Design and development: This involves creating the initial design for the shoe dryer and refining it through testing and prototyping.

Raw materials sourcing: This involves acquiring the various raw materials that will be used in the production of the shoe dryer, such as plastics, metals, and electronics.

Manufacturing: This involves using various tools and equipment to transform the raw materials into the finished product. This can include processes such as injection molding, metal stamping, and assembly line production.

Testing and quality control: This involves ensuring that the shoe dryer meets all relevant safety and performance standards before it is shipped to customers.

The production of a shoe dryer may also involve the use of advanced manufacturing techniques and technologies, such as robotics and computer-controlled equipment, to ensure efficiency and accuracy in the manufacturing process.

English

English 中文简体

中文简体

MORE

MORE MORE

MORE